DTF Printing (Direct-to-Film) is a game-changing technique offering efficient, high-quality printing on various surfaces like plastic and fabric. By skipping traditional steps, it enables rapid production—delivering transfers in as little as 24 hours—and is transforming industries such as signmaking, packaging, and textiles. The rise of streaming services has accelerated the demand for faster film distribution, further driving the popularity of DTF Printing among film studios. Innovations in dye sublimation, latex inkjet printing, and automated systems are revolutionizing DTF Printing's efficiency and accuracy.

In today’s fast-paced media landscape, the demand for direct-to-film (DTF) printing has surged, driven by the need for quick and efficient content delivery. Expedited production of DTF transfers within 24 hours is no longer a concept but a reality, revolutionizing the film industry. This article delves into the intricacies of DTF printing, explores the urgency for accelerated production, examines the feasibility of 24-hour turnaround times, highlights cutting-edge technologies driving speed improvements, discusses quality control challenges, and uncovers potential benefits and applications of this game-changing process.

- Understanding Direct-to-Film (DTF) Printing: A Brief Overview

- The Need for Expedited Production in the Film Industry

- Exploring 24-Hour Turnaround Times: Is it Feasible?

- Technology and Innovations Driving DTF Print Speed

- Ensuring Quality Amidst Rapid Production: Challenges and Solutions

- Potential Benefits and Applications of 24-Hour DTF Transfers

Understanding Direct-to-Film (DTF) Printing: A Brief Overview

Direct-to-Film (DTF) printing is a cutting-edge technique that allows for the creation of high-quality, full-color images directly onto various film surfaces, including plastic and metal. This innovative process eliminates the need for traditional intermediate steps, such as separating colors or using plates, making it an efficient and versatile option for a range of applications. DTF Printing offers unparalleled precision, ensuring that every detail from the original source material is accurately reproduced on the final print.

The simplicity of the method lies in its ability to use inkjet printers to deposit pigment onto the film surface, creating a durable and long-lasting image. This technology has revolutionized many industries, particularly in fields like signmaking, packaging design, and promotional products. With DTF Printing, businesses can now offer expedited production times, delivering direct-to-film transfers within 24 hours, catering to the fast-paced demands of modern marketing and branding strategies.

The Need for Expedited Production in the Film Industry

In today’s fast-paced media landscape, the film industry constantly seeks innovative ways to meet audience demands for fresh content. This has led to a significant surge in popularity for direct-to-film (DTF) transfers, offering viewers instant access to their favorite movies and shows. However, traditional production timelines can be lengthy, often taking weeks or even months to complete. To stay competitive and cater to modern consumer expectations, there’s a growing need for expedited production methods, particularly for DTF Printing.

With the rise of streaming services and on-demand entertainment, audiences no longer have to wait for theatrical releases or long periods for home media availability. This shift has prompted film studios and content creators to explore faster production techniques, ensuring they can deliver high-quality, timely releases. Expedited DTF Printing offers a solution by significantly reducing the time between content creation and its accessibility to the public, revolutionizing how films are distributed and consumed.

Exploring 24-Hour Turnaround Times: Is it Feasible?

Technology and Innovations Driving DTF Print Speed

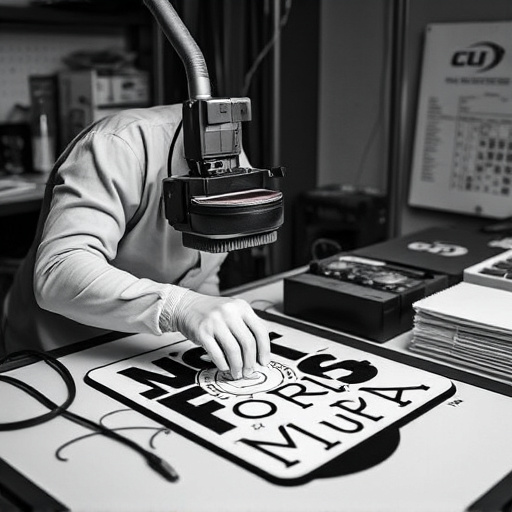

The expedited production of direct-to-film (DTF) transfers within 24 hours is made possible by groundbreaking technology and innovations that have dramatically increased print speed. Digital printing technologies, such as dye sublimation and latex inkjet printing, have revolutionized DTF Printing. Dye sublimation, for instance, involves heating dyes to a gas state, allowing them to penetrate the film surface and create vibrant, high-resolution images. This process has been refined to significantly reduce production time without compromising quality.

Latex inkjet printing, another significant advancement, uses liquid latex inks that cure upon exposure to light or air. This technology enables precise color reproduction and fine detail, ensuring that even intricate graphics are accurately transferred to the film. Automated feed systems and advanced control software further streamline the DTF Printing process, minimizing human intervention and maximizing efficiency, thereby facilitating the rapid turnaround time of 24 hours.

Ensuring Quality Amidst Rapid Production: Challenges and Solutions

In the race to deliver direct-to-film (DTF) prints swiftly, maintaining quality becomes a delicate balance. The primary challenge lies in balancing speed with precision, especially with 24-hour production targets. Each step of the process, from raw material preparation to print and finish, demands meticulous attention to detail. To overcome this, specialized equipment and skilled technicians are essential; they ensure consistent performance throughout the rapid production cycle.

One solution is implementing rigorous quality control measures at every stage. This includes using high-quality materials and inks designed for fast production without compromising visual integrity. Advanced scanning and printing technologies also play a crucial role, enabling precise color reproduction and sharp details, even under tight deadlines. Regular calibration and maintenance of equipment further ensure consistent output quality, addressing potential issues before they impact the final product.

Potential Benefits and Applications of 24-Hour DTF Transfers

The expedited production of direct-to-film (DTF) transfers within 24 hours offers a myriad of benefits and applications across various industries. In today’s fast-paced world, where speed and efficiency are paramount, DTF Printing has emerged as a game-changer. It enables businesses to streamline their workflow, reduce turnaround times, and meet the demands of modern consumers who expect immediate access to content.

One of the key advantages is its versatility; DTF Transfers can be applied to a wide range of media, from small-scale personal projects to large-format advertising displays. This technology allows for rapid prototyping and small batch production, making it ideal for short-run printing needs. Moreover, the 24-hour turnaround time means filmmakers, event organizers, and marketers can quickly convert their digital assets into physical, high-quality prints without sacrificing quality or speed.