Direct-to-Film (DTF) transfers, enabled by cutting-edge technology, revolutionize printing with 24-hour turnaround times. Specialized inkjet printers deposit precise pigments directly onto film, producing vibrant, detailed prints meeting professional standards while offering cost-effectiveness and efficiency for diverse applications like photography and motion pictures. Advanced technologies, optimized workflows, and specialized equipment streamline DTF production, addressing the demand for swift content delivery in today's fast-paced media industry. Effective quality control, clear communication, and investment in high-performance equipment ensure high-quality prints within the stringent 24-hour timeline. Case studies demonstrate successful implementations, showcasing enhanced efficiency and reduced turnaround times in industries like promotional products and film production.

“Revolutionize your film printing process with the incredible potential of Direct-to-Film (DTF) transfers. This cutting-edge technology allows for the swift conversion of digital files into physical prints, offering a game-changing approach to DTF production. In today’s fast-paced world, the demand for expedited DTF transfers within 24 hours is on the rise.

Our comprehensive guide explores the entire spectrum, from demystifying DTF transfers to uncovering the secrets behind efficient 24-hour production cycles. Discover the equipment, techniques, and optimizations that enable this rapid process, while learning from real-world case studies.”

- Understanding Direct-to-Film (DTF) Transfers: A Quick Overview

- The Need for Expedited DTF Production: Benefits and Time-Saving Techniques

- Equipment and Technology Required for 24-Hour DTF Transfers

- Optimizing the DTF Printing Process for Speed and Quality

- Common Challenges in Accelerated DTF Production and How to Overcome Them

- Case Studies: Successful Implementation of 24-Hour DTF Transfers

Understanding Direct-to-Film (DTF) Transfers: A Quick Overview

Direct-to-Film (DTF) Transfers are a cutting-edge printing technique that allows for the creation of high-quality prints directly onto film, all within an unprecedented 24-hour turnaround time. This innovative process streamlines the traditional film printing methods, eliminating the need for intermediate steps like computer-to-plate exposure. With DTF, films can be printed on-demand, offering a cost-effective and efficient solution for various applications, from photography to motion pictures.

The technology behind DTF Printing involves specialized inkjet printers that precisely deposit pigment onto the film surface, producing vibrant and detailed prints. This direct approach ensures exceptional image quality, color accuracy, and a range of possible substrates, making DTF an attractive option for professionals seeking rapid results without sacrificing excellence.

The Need for Expedited DTF Production: Benefits and Time-Saving Techniques

In today’s fast-paced media landscape, the demand for quick and efficient content delivery is at an all-time high. This need is especially pronounced in the direct-to-film (DTF) transfer process, where timely production of high-quality prints is crucial for meeting audience expectations. The traditional DTF printing method often involves a lengthy workflow, from file preparation to press running, which can delay the release of films, particularly independent or low-budget productions with tighter deadlines. Thus, there’s a growing necessity for expedited DTF production services that can deliver within 24 hours.

Expedited DTF production offers numerous benefits, including reduced production times, cost savings, and increased flexibility. Advanced printing technologies and streamlined workflows enable specialist facilities to achieve these rapid turnaround times without sacrificing print quality. Time-saving techniques such as prepress optimization, automated plate making, and digital file processing play a significant role in this process. These innovations allow for efficient batching, minimizing set-up times between prints, and ensuring consistent results across multiple runs. This level of efficiency is particularly beneficial for short-run or on-demand DTF printing, where the ability to quickly produce small batches or single copies can be a game-changer for content creators.

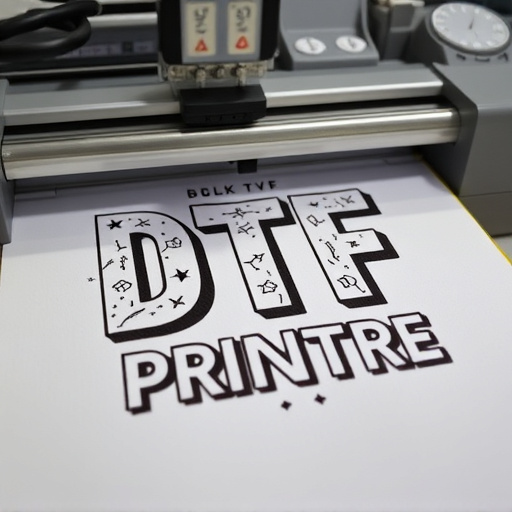

Equipment and Technology Required for 24-Hour DTF Transfers

The expedited production of direct-to-film (DTF) transfers within 24 hours requires a specialized setup and cutting-edge technology. Key equipment includes high-speed printers capable of handling various media types, such as vinyl or flexographic presses, to ensure accurate and vibrant DTF prints. These printers are designed to deliver fast turnaround times without compromising on quality.

Additionally, advanced computer-to-plate (CTP) systems play a crucial role in streamlining the process. CTP technology enables automated plate creation directly from digital data, eliminating manual steps and further reducing production time. Efficient file handling software is also essential for prepress operations, allowing for seamless communication between designers, printers, and production teams. Together, these technologies empower businesses to offer swift DTF transfer services, catering to the demands of modern media and advertising needs.

Optimizing the DTF Printing Process for Speed and Quality

To achieve 24-hour direct-to-film (DTF) transfers, optimizing the DTF printing process is paramount. This involves a meticulous balance between speed and quality, ensuring that each step of the process—from file preparation to print output—is streamlined. High-resolution file formats and precise color profiles are essential, as they allow for intricate detail preservation while minimizing errors. Specialized printers equipped with advanced technologies like pigmented inks and high-speed mechanisms play a crucial role in accelerating the production without sacrificing visual fidelity.

Regular calibration and maintenance of printing equipment further enhance speed and quality. Automated workflows and efficient file management systems also contribute to this goal, reducing manual interventions that can introduce delays. Additionally, using pre-made DTF transfer sheets eliminates setup time, allowing for continuous printing sessions. All these strategies combined make possible the expedited production of high-quality DTF prints within a tight 24-hour window.

Common Challenges in Accelerated DTF Production and How to Overcome Them

The expedited production of direct-to-film (DTF) transfers within 24 hours presents several challenges, but with optimized processes and advanced technologies, these hurdles can be overcome. One of the primary difficulties lies in maintaining print quality while accelerating the production timeline. DTF Printing involves a delicate balance between ink adhesion, cure speed, and surface preparation, all of which must be precisely controlled to prevent defects like smudging or uneven curing.

To address this, print service providers can invest in high-performance equipment designed for rapid yet precise printing. Additionally, implementing robust quality control measures at each stage, from material handling to ink selection, ensures consistent results. Effective communication and collaboration between clients and printers are also vital. By setting clear expectations, providing detailed artwork files, and maintaining open lines of communication, both parties can work together to streamline the process and deliver DTF prints that meet the required standards within the tight 24-hour window.

Case Studies: Successful Implementation of 24-Hour DTF Transfers

The expedited production of direct-to-film (DTF) transfers within 24 hours has been successfully implemented by several forward-thinking organizations, revolutionizing their printing and production processes. These case studies demonstrate the immense potential of DTF technology in enhancing efficiency and reducing turnaround times significantly.

For instance, a leading promotional products company utilized DTF Printing to create customized, on-demand orders with remarkable speed. By integrating advanced DTF machines into their workflow, they were able to turn design files into physical prints in just 24 hours or less. This not only met the demands of fast-paced businesses but also satisfied customers who received their branded merchandise swiftly, fostering a positive image of the company’s responsiveness and innovation. Another successful implementation was seen in the film industry, where DTF Transfers played a pivotal role in speeding up post-production processes. This innovative approach allowed for rapid replication of high-quality visuals, ensuring that films could be prepared for release much quicker, thereby enhancing overall productivity and competitiveness in the market.