Direct to Film (DTF) printing offers efficient, high-quality on-demand production for short runs and small batches. Key steps include printer settings optimization, sheet selection, thorough pre-production testing, and strict quality control protocols using advanced imaging. Same Day DTF Printing demands precision to meet deadlines while ensuring vibrant, consistent results with minimal waste.

In the fast-paced world of print on demand, same day DTF (Direct to Fabric) printing offers a unique advantage. However, achieving consistent quality requires meticulous attention to detail. This article guides you through essential steps to ensure seamless production. From grasping DTF printing fundamentals to optimizing quality control, we cover everything you need to know. By implementing these strategies, you’ll minimize errors and deliver high-quality same day DTF prints, ensuring customer satisfaction.

- Understanding DTF Printing Basics

- Pre-Production Preparations and Checks

- Optimizing Quality Control Processes

Understanding DTF Printing Basics

Direct to Film (DTF) printing is a versatile and efficient method used in various industries for producing high-quality prints on demand. This process involves transferring an image or design directly onto a film or substrate, eliminating the need for traditional plates. In the context of Same Day DTF Printing, businesses can swiftly create custom prints, making it ideal for short-run projects, prototypes, and small batch production. Understanding the fundamentals of DTF printing is crucial to ensuring accurate results and minimizing errors in production.

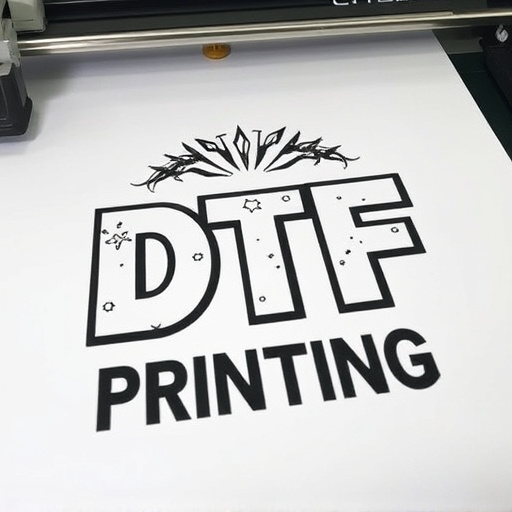

The core of DTF printing lies in the use of specialized printers and transfer sheets. A direct to film printer utilizes inkjet technology to apply pigment or dye onto a transparent film, creating a negative of the desired image. This negative then acts as a stencil, allowing ink to pass through specific areas when pressed against a substrate, such as fabric, paper, or plastic. The precision of this process ensures sharp details and vibrant colors in the final print. By mastering the settings on their direct to film printers and selecting appropriate DTF transfer sheets, manufacturers can achieve consistent quality, reduce waste, and deliver orders on time, making it a reliable solution for Same Day DTF Printing production.

Pre-Production Preparations and Checks

Before initiating same day DTF printing production, meticulous pre-production preparations and checks are paramount. This involves verifying all design files for accuracy and compatibility with your DTF printer. Ensure that the designs are at the correct resolution, color mode, and have the appropriate bleed settings to avoid any unforeseen issues during printing.

Additionally, inspect your inventory of dtf transfer sheets for any damage or expiration dates. Using outdated or damaged sheets can lead to subpar prints and potential equipment malfunctions. Verify the quality of your direct to film personalized hoodies or other DTF print products by conducting test prints on scrap material, allowing you to identify and address any potential problems before committing to full-scale production.

Optimizing Quality Control Processes

To ensure optimal quality in same day DTF printing, businesses should focus on streamlining their quality control processes. This involves implementing rigorous inspection protocols at every stage of production. For instance, before cutting, check for any misalignments or imperfections in the design, ensuring the DTF for apparel aligns perfectly with the garment’s shape and cut. After application, conduct thorough visual inspections to detect any air bubbles, creases, or improper adhesion.

Using advanced technologies like digital cameras and software for enhanced imaging can aid in identifying minute defects that might be missed by the naked eye. Additionally, incorporating cold peel DTF transfers into your quality control routine allows for easier removal of transfers for re-application or to identify any issues with the printing process itself. Regular training of staff on quality standards and consistent use of these techniques will significantly reduce errors in same day DTF printing.

Same day DTF (Direct to Fabric) printing offers a fast and efficient solution for on-demand production, but minimizing errors is crucial for maintaining quality. By understanding the fundamentals of DTF printing, conducting thorough pre-production checks, and optimizing quality control processes, businesses can ensure precise and consistent results. These strategies are essential for delivering high-quality products while meeting tight deadlines, making same day DTF printing a reliable option in today’s fast-paced market.